Unleashing Innovation in Urban Cleaning: The Role of Road Sweeper Manufacturers in Integrating 3D Printing Technologies

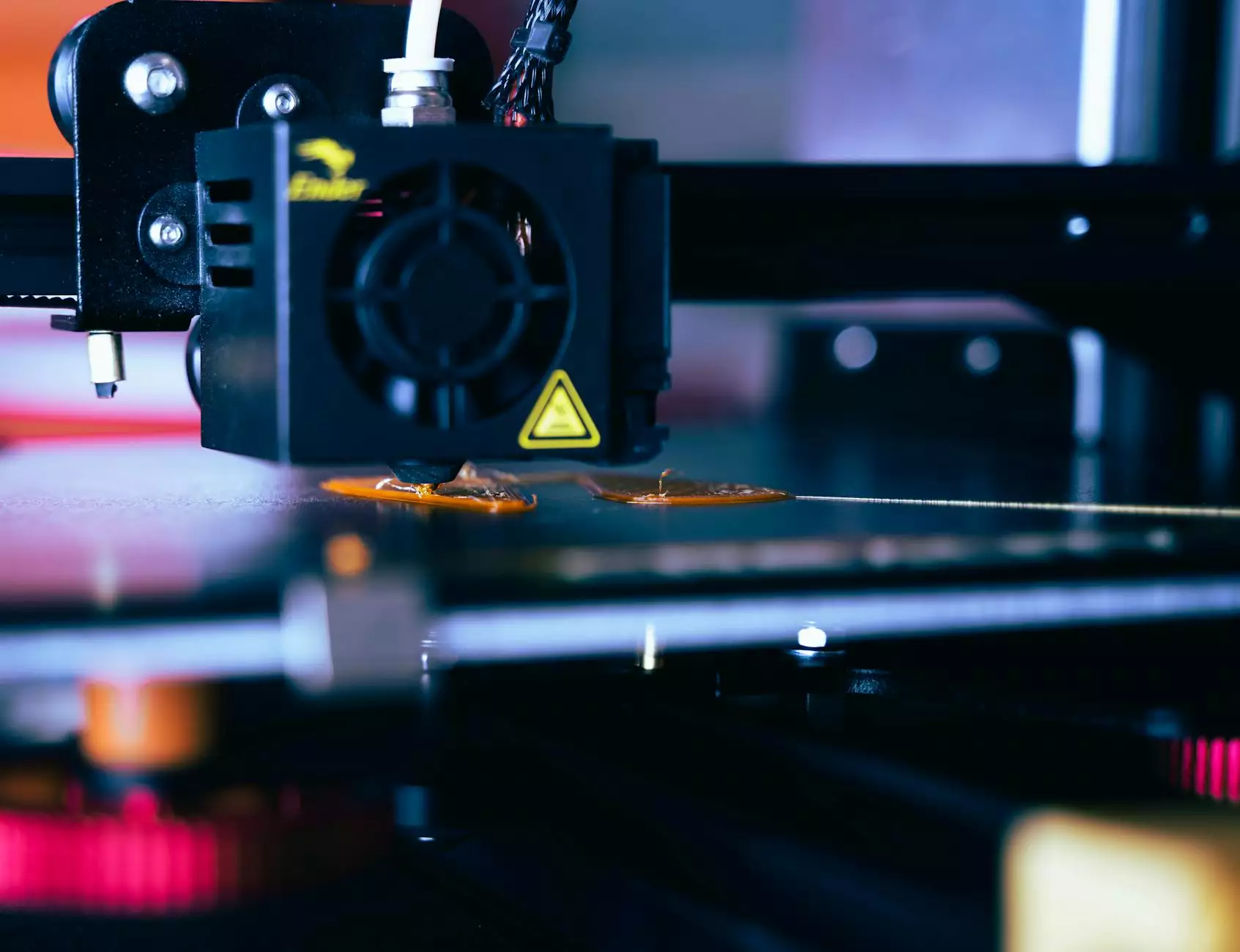

In the rapidly evolving landscape of manufacturing and environmental sustainability, road sweeper manufacturers are pioneering transformative approaches to enhance urban street cleaning equipment. Among the most significant advancements is the integration of 3D printing technologies, which have revolutionized design, production, and maintenance processes. This comprehensive exploration delves into how industry-leading companies like ceksansweepers.com are leveraging 3D printing to redefine standards, boost efficiency, and foster sustainable innovation in the realm of city cleaning solutions.

Understanding the Importance of Road Sweeper Manufacturing in Modern Urban Management

Urban environments face persistent challenges related to pollution, waste management, and infrastructure maintenance. Effective street sweeping is crucial for maintaining public health, aesthetic appeal, and environmental quality. Road sweeper manufacturers are at the forefront of developing robust, reliable, and innovative machinery that can meet these demands. Their role extends beyond mere equipment production to include:

- Automation and smart technology integration for efficiency and precision

- Sustainable operation utilizing eco-friendly materials and energy-saving features

- Customization to suit specific regional and infrastructural requirements

- Ease of maintenance and durability to minimize downtime and lifecycle costs

As urban centers grow, the importance of adaptable and technologically advanced street cleaning solutions becomes undeniable. Industry innovators recognize this and are adopting new manufacturing paradigms—most notably, 3D printing.

How 3D Printing Transforms Manufacturing Processes in the Street Sweeping Industry

3D printing, also known as additive manufacturing, is revolutionizing traditional production methods by enabling rapid prototyping, customized component fabrication, and complex design realization with unmatched precision. For road sweeper manufacturers, this technology offers numerous strategic advantages:

- Accelerated prototyping: Reducing the time from concept to functional prototype allows for quicker testing, iteration, and development. This means innovative features and ergonomic designs are brought to market faster.

- Cost-efficient production of spare parts: On-demand printing of complex, hard-to-source components minimizes inventory costs and reduces equipment downtime due to supply chain delays.

- Customization and bespoke solutions: Tailoring street sweeper components to local requirements or specific projects becomes feasible without large-scale tooling investments.

- Development of lightweight yet durable parts: Reducing weight improves vehicle efficiency and maneuverability; 3D printing enables the construction of parts with optimized geometries.

- Enhanced sustainability: Using environmentally friendly materials and reducing waste aligns with the global push toward eco-conscious manufacturing.

Leading companies like ceksansweepers.com are actively investing in 3D printing capabilities to push the boundaries of innovation in street cleaning equipment.

Key Areas Where 3D Printing Benefits Road Sweeper Design and Production

1. Rapid Prototyping and Design Optimization

Creating detailed prototypes quickly allows manufacturers to test new designs in real-world scenarios. This accelerates the refinement of sweeping mechanisms, water jet features, and dust suppression systems, ensuring optimal performance before mass production.

2. Customizable Components for Diverse Urban Environments

Different cities have varying infrastructure and pollution challenges. 3D printing enables the production of tailored solutions—such as uniquely shaped brushes, specialized nozzles, and adaptive chassis components—that fit precise operational needs.

3. Reduced Production Costs and Supply Chain Risks

By manufacturing spare parts on-site or locally through 3D printing, companies reduce dependency on international suppliers, cut transportation costs, and minimize delays. This agility results in improved service levels and higher customer satisfaction.

4. Sustainable and Eco-friendly Manufacturing

Employing biodegradable or recyclable materials in 3D printing aligns with eco-conscious initiatives. Additionally, waste reduction during manufacturing supports environmental goals and enhances corporate social responsibility.

The Future of Street Sweeping Technology: Integrating 3D Printing with Intelligent Systems

Foreseeing the future, road sweeper manufacturers are merging 3D printing with advances in automation, IoT, and AI to develop intelligent, autonomous cleaning vehicles. The synergy of these technologies promises:

- Smart sensors for real-time dirt detection and route optimization

- Autonomous operation reducing human labor costs and improving safety

- Predictive maintenance facilitated through 3D-printed diagnostic parts and sensors

- Enhanced durability and custom-fit components adapted to specific environments

This convergence leads to resilient, efficient, and environmentally friendly street cleaning systems capable of self-maintenance and continuous performance improvement.

Leading Industry Players Embracing 3D Printing in Road Sweeper Manufacturing

Several pioneering companies have recognized the strategic importance of 3D printing:

- ceksansweepers.com: Innovator in integrating 3D printing with their comprehensive range of street cleaning machinery, leading to customized, lightweight, and durable components that enhance operational efficiency.

- Global OEMs investing in additive manufacturing labs to prototype and test new cleaning solutions.

- Regional manufacturers adopting 3D printing for rapid local production, reducing lead times and fostering community-specific solutions.

The continued investment and research in this domain herald a new era of manufacturing excellence and innovative urban cleanliness solutions.

Challenges and Considerations in Applying 3D Printing to Road Sweeper Manufacturing

Despite its advantages, integrating 3D printing into manufacturing processes presents challenges, including:

- Material limitations: Not all materials are suitable for heavy-duty or high-wear parts used in street sweepers.

- Scalability concerns: Producing large components or high volumes requires advanced printers and processes.

- Quality assurance: Ensuring consistent strength, durability, and safety standards necessitates rigorous testing and quality control protocols.

- Investment costs: High initial investment in 3D printing equipment and training can be a barrier for smaller manufacturers.

Innovative solutions and ongoing research continue to address these hurdles, making the adoption of 3D printing more accessible and effective.

Conclusion: Embracing Innovation for Sustainable and Efficient Urban Cleaning Solutions

Ultimately, the integration of 3D printing by road sweeper manufacturers marks a pivotal step toward smarter, more sustainable, and highly efficient urban cleaning operations. Companies like ceksansweepers.com exemplify how technological innovation can lead to superior product development, reduced environmental impact, and customized solutions for diverse city infrastructures.

As the industry advances, continued investment in additive manufacturing, smart system integration, and eco-conscious materials will set new standards, ensuring cleaner, healthier cities worldwide. Whether through faster prototyping, cost savings, or enhanced durability, 3D printing is undeniably shaping the future of road sweeper manufacturing.

Embracing these cutting-edge technologies not only elevates manufacturer capabilities but also promotes sustainable urban growth, ensuring that city streets remain pristine while supporting environmental and economic well-being.